What Are the Disadvantages of Air Dry Clay?

When considering air-dry clay for your next project, it's crucial to be aware of its disadvantages. Thin sections of your creation can be particularly fragile and prone to breaking. As the clay dries, shrinkage may lead to warping or cracking, making it unsuitable for functional items. Its porous nature means it's not food-safe. The drying process can take significant time and requires careful monitoring. Additionally, sealing is necessary to improve durability, adding complexity. Issues with color application can also arise, as the clay may not take paint evenly or may require multiple coats.

Fragility of Thin Pieces

When working with air dry clay, the fragility of thin pieces presents a significant challenge. Delicate features such as legs or intricate designs are particularly prone to breaking due to the material's inherent limitations. These thin sections tend to crack or snap under even slight pressure, necessitating careful handling.

The drying process further complicates matters. As air dry clay dries, it shrinks, causing thinner sections to curl or warp. This not only affects the overall appearance but can also compromise the functionality of your piece. Controlling the drying environment meticulously is crucial to minimize these issues.

Attaching thin elements to larger structures adds another layer of complexity. The slip and score method, commonly used to join clay parts, might not provide sufficient strength for fragile connections. Extra caution and perhaps design adjustments are needed to ensure stability.

Given these limitations, thoughtful design considerations are essential. Avoid overly intricate details that are likely to break during or after creation. By understanding and navigating the fragility of thin pieces, you can better manage the challenges posed by air dry clay.

Not Food Safe

Air-dry clay isn't suitable for food-related items due to its porous nature, which can absorb moisture and harbor bacteria. Hence, it should be used solely for decorative purposes, such as creating planters or jewelry trays. This characteristic makes air-dry clay inappropriate for dishes, utensils, or any items that come into direct contact with food.

When crafting with air-dry clay, you can explore various creative projects without concerns about food safety. Its moisture-absorbing properties emphasize the need to limit its use to non-functional items to avoid potential health risks.

For educators and hobbyists, it's crucial to inform participants that air-dry clay should not be used for serving or storing food. Clear communication ensures safety and protects the integrity of your creative endeavors.

Longer Drying Times

One significant drawback of using air-dry clay is its prolonged drying time, which can disrupt project schedules. Careful planning and patience are essential, as rushing the process often causes cracks or structural problems. In educational settings, this extended drying period can complicate scheduling and delay future lessons.

Time Management Challenges

Managing time effectively becomes a significant challenge due to the extended drying times of air-dry clay, which typically requires 24 to 72 hours to fully set. For students working on projects, this drying time can cause considerable delays. Planning project timelines carefully is essential, especially in a classroom setting where multiple projects might be in progress simultaneously. The longer drying period also means thicker pieces can take even longer, complicating scheduling further.

Additionally, if the air-dry clay isn't monitored closely, it can crack or warp as it dries, which delays completion and necessitates extra time for repairs. Environmental factors like humidity and temperature can influence these outcomes, making it harder to stick to a schedule.

In a classroom or workshop setting, the need for extended drying periods can severely limit the number of projects that can be completed in a given timeframe, affecting overall productivity. This challenge forces you to allocate more time for each project, ultimately slowing down the entire learning process. Effective time management becomes essential but challenging, often requiring careful planning and adjustments.

Patience and Planning

Navigating the challenges of time management requires patience and careful planning, especially with the extended drying times of air-dry clay. Typically, you should allocate at least 24 hours for drying, though several days may be necessary depending on the piece's thickness and environmental conditions. High humidity levels can significantly prolong the drying process, necessitating even more patience and strategic foresight.

Beyond just keeping track of time, it's crucial to consider the shrinkage that occurs during drying. Air-dry clay can shrink between 5-15%, potentially altering the final appearance and details of your creation. To mitigate cracking, employ slow drying techniques. Covering your pieces with plastic can help ensure uniform drying and reduce the risk of cracks.

Effective planning becomes essential when managing multiple projects. Anticipate drying times and integrate them into your overall timeline. This foresight ensures that your hard work pays off and you avoid compromised results due to rushed drying.

Classroom Scheduling Issues

Classroom scheduling can be challenging due to the extended drying times required for air-dry clay projects. Air-dry clay typically needs at least 24 hours to harden, and thicker pieces may take several days to fully cure. This extended drying period can disrupt your classroom plans, making it difficult to fit multiple projects into a limited timeframe.

You may need to allocate extra time for students to revisit their projects, complicating lesson planning and classroom management. Moreover, ensuring that projects are ready for handling or display adds another layer of complexity. If you have presentations or exhibitions scheduled, the drying times can cause delays, affecting these events.

Quick turnaround projects become nearly impossible, as coordinating the drying process is crucial to ensure all students complete their work effectively. Therefore, you'll need to plan your curriculum with these drying times in mind, potentially limiting the variety and number of projects you can undertake. Consequently, classroom scheduling issues can significantly impact your ability to manage and execute air-dry clay projects smoothly.

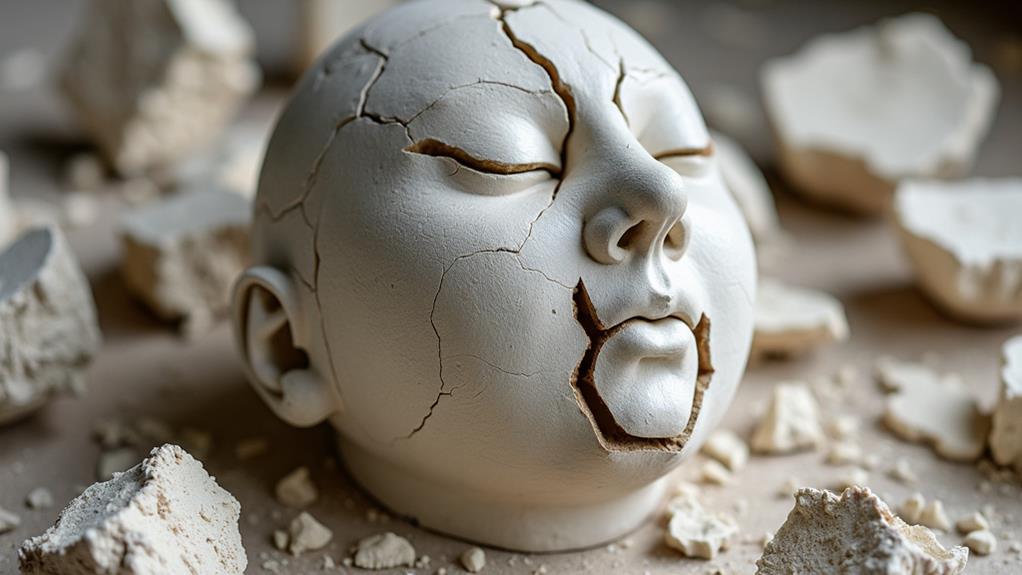

Susceptible to Cracking

Air dry clay is particularly prone to cracking, especially when it dries too quickly in environments with low humidity or high temperatures. Rapid moisture loss can lead to fractures, especially in thin or delicate sections of your project. Additionally, uneven thickness within the clay can cause stress, as thicker areas dry more slowly than thinner ones, increasing the potential for cracks.

To mitigate these issues, consider the following preventative measures:

- Dry slowly: Allow your pieces to dry at room temperature, avoiding direct sunlight.

- Cover with plastic: Use a plastic bag to cover your project, helping to retain moisture and control the drying process.

- Smooth edges: Regularly smooth edges and surfaces to maintain even thickness throughout the piece.

- Monitor humidity: Keep the drying environment at a stable humidity level to prevent rapid drying.

Shrinkage During Drying

Shrinkage during drying is another significant challenge when working with air-dry clay. As the clay dries, it typically shrinks by 5-15%, potentially altering the dimensions of your piece. This shrinkage can lead to warping or distortion, particularly in intricate designs or sections with varying thicknesses. Uneven shrinkage is a common issue and can cause cracks, compromising the structural integrity of your work.

Several factors influence the extent of shrinkage, including clay thickness, environmental humidity, and air circulation during drying. Thicker clay sections tend to dry more slowly than thinner ones, leading to uneven shrinkage and potential cracking. To minimize these issues, it's crucial to maintain a consistent thickness throughout your project. Additionally, drying your pieces slowly at room temperature can help mitigate shrinkage-related problems.

Limited Strength

One of the main drawbacks of air-dry clay is its limited strength, which can significantly hinder creative possibilities. Unlike oven-bake clays, air-dry clays are generally less durable. This inherent fragility restricts their use for large-scale or intricate 3D creations. The material is prone to breaking or chipping under pressure or impact, making it unsuitable for functional items that need to withstand regular use.

When working with air-dry clays, rolling the material too thin can lead to cracks, compromising the structural integrity of your project. Additionally, the open-air drying process can cause shrinkage of 5-15%, further affecting the strength and detail of the final product.

To summarize, the limitations of air-dry clays include:

- Less durability compared to oven-bake clays, limiting their use for intricate or large-scale projects.

- Prone to breaking or chipping under pressure or impact.

- Thin rolling can lead to cracks, compromising structural integrity.

- Open-air drying causes shrinkage, impacting strength and detail.

Understanding these limitations can help you make more informed decisions when working with air-dry clay.

Color Application Challenges

In addition to limited strength, another significant challenge when working with air-dry clay is the application of color. Traditional glazing methods aren't an option, which restricts your finishing choices. The porous nature of air-dry clay often necessitates multiple layers of water-based paints like acrylics for full coverage, extending your project timeline.

Some paints can make the clay tacky or alter its texture, complicating your creative process. This tackiness is particularly frustrating if you're aiming for a smooth, even finish. Additionally, certain coloring mediums don't adhere well to air-dry clay, leading to uneven application or peeling after the paint dries. You might think you've achieved the perfect look, only to see it flake away over time.

The potential for cracking in air-dry clay compounds these issues. Heavy paint layers can exacerbate this problem, making it vital to apply color with a light touch. Balancing adequate coverage while avoiding thickness that leads to cracks is a delicate process, requiring patience and skill. Consequently, mastering color application on air-dry clay presents its own set of challenges.

Not Suitable for Large Projects

For large projects, air dry clay presents significant challenges due to its limited structural integrity and propensity to crack. The material's size constraints and shrinkage during drying complicate the stability and detail needed for substantial pieces. Consequently, air dry clay is more suitable for smaller, lightweight creations rather than large-scale sculptures.

Limited Structural Integrity

Air dry clay, due to its inherent weaknesses, is not ideal for large-scale projects requiring strong structural integrity. Unlike kiln-fired clays, air dry clay is significantly weaker, often resulting in breakage or deformation, especially in intricate or heavy designs. This lack of durability makes it unsuitable for projects where stability is crucial.

When working with air dry clay, you'll notice its fragility. Thin components, like legs or arms on sculptures, are particularly prone to snapping or cracking. Additionally, as the clay dries, it shrinks by 5-15%, which can affect the final dimensions and stability of your piece. This shrinkage complicates the creation of larger, cohesive structures without compromising their integrity.

Key limitations of air dry clay include:

- Limited structural integrity: Unsuitable for large or intricate designs.

- Fragility: Particularly susceptible to snapping, especially in thin parts.

- Shrinkage: Expect a 5-15% reduction in size during drying.

- Reinforcement required: To enhance durability, you may need to use reinforcing materials or consider alternative clays.

Understanding these limitations can help you avoid frustration and ensure your projects meet your expectations.

Prone to Cracking

One of the significant drawbacks of air dry clay is its tendency to crack, making it unsuitable for large projects. When air dry clay dries too quickly or when pieces are rolled too thin, it becomes highly prone to cracking, which can severely compromise the structural integrity of your work. Even with proper drying techniques, such as slow drying and covering your projects to control moisture loss, cracking can still occur, especially in larger creations.

As air dry clay dries, it undergoes a shrinkage of 5-15%, which can result in a loss of detail and aesthetic appeal. This shrinkage further increases the likelihood of cracks forming, particularly in delicate features or thin extensions. These fragile parts are especially vulnerable during the drying phase, making it difficult to maintain the original design intent.

Due to its limited strength, air dry clay isn't ideal for large-scale projects. The material may not support its own weight if constructed too large, leading to further cracking and structural failure. Therefore, if you're planning a large or intricate project, air dry clay might not be the best choice due to these inherent limitations.

Size Constraints

Although air dry clay is a versatile and accessible medium for many artists, it faces significant challenges for large projects due to its inherent size limitations. One primary issue is that air dry clay typically shrinks between 5-15% during the drying process, potentially distorting the size and details of larger creations.

Additionally, air dry clay's limited structural strength compared to oven-bake clays makes it impractical for large-scale projects that require durability. Thicker pieces, in particular, can take several days to dry, which is not ideal for tight schedules.

Another concern is the increased risk of cracking and warping as larger pieces dry. Close monitoring is required to ensure even moisture retention, which can be cumbersome. Finally, the fragility of air dry clay restricts the creation of expansive or intricate designs, as thin sections like arms or legs can easily break off.

Key challenges include:

- Shrinkage of 5-15% during drying

- Limited structural strength

- Extended drying times for thicker pieces

- Increased risk of cracking and warping

Requires Sealing for Durability

To enhance the durability of your air dry clay creations, sealing them is crucial due to the material's porous nature. Air dry clay absorbs moisture, making it susceptible to water damage if not sealed. Without this essential step, your projects may crack and deteriorate over time, particularly in humid environments.

Applying a sealant like varnish or an acrylic sealer significantly improves the water resistance of your clay items. This not only protects your creations from moisture but also provides a smoother finish and a glossy appearance, adding an aesthetic touch to decorative pieces. However, sealing adds an extra layer of complexity and time to your projects.

You must wait for the clay to dry completely before applying any protective coatings, which increases the total project time. This additional step can be inconvenient, especially if you're eager to see your finished product or working under a tight schedule. While sealing offers numerous benefits, it also makes the crafting process more time-consuming and complex, a notable drawback of using air dry clay.